NTT Corporation (president and CEO: Akira Shimada) has developed an ultra-sensitive detection technology utilising an optical fibre that can measure particles and viscosity at desired locations in liquids.

The development of technologies to detect and evaluate the viscosity of liquids and the substances in liquids with high sensitivity is vital for a wide range of use cases spanning the rheology and biology fields to medical and materials applications. Sensing technology using mechanical resonators is attracting particular attention as a simple way to perform measurements and evaluations by inserting a sensor directly into a liquid. Until now, electrical measurements using quartz resonator sensors with a diameter of about one centimeter have typically been used, but the development of sensing technologies that can dramatically improve detection sensitivity and spatial resolution is underway.

In this research, hair-size mechanical resonators made of fine glass wire were utilised to achieve a sensing technology with high spatial resolution that can measure the fluidic properties and the mass of particles in liquids with ultrahigh sensitivity. This sensing technology, which can be read by an optical fibre, is designed for application to IoT sensors that can perform operations difficult to achieve with conventional methods, such as high-resolution particle detection at desired locations in liquids and the characterisation of local fluidic properties in non-uniform solutions.

The results were published online in the American scientific journal “Science Advances” on 2 November 2022 (EDT). This work was partly supported by JSPS KAKENHI (21H01023).

Background and outcome overview

The development of sensors that enable highly sensitive measurements in liquids is vital in a wide range of fields such as bio- and nano-technology. For example, mass sensors that can detect biomolecules with high sensitivity are important for medical applications such as biochips. In addition, the development of sensors that can accurately evaluate the density and viscosity of spatially non-uniform liquids is important for the creation of functional fluids and applications in rheology.

Quartz resonator sensors have been commercialised as sensors that can be inserted directly into liquids to measure the fluidic properties and the mass of particles in liquids. When a quartz resonator is immersed in a liquid, its vibration characteristics are affected by the density and viscosity of the liquid. When the particles adhere, the vibration characteristics also change. Therefore, the information in the liquid can be read by measuring the vibration characteristics. Until now, electrical measurements using quartz with a diameter of about one centimeter have been widely performed, but dramatic improvements in spatial resolution and detection sensitivity have been ushering in developments.

In this research, a mechanical resonator made of fine glass wire with a cross-section several orders of magnitude smaller than conventional sensors was utilised to achieve sensing with a high spatial resolution that can measure the characteristics of liquids and the mass of particles in liquids with ultrahigh sensitivity.

Experiment overview

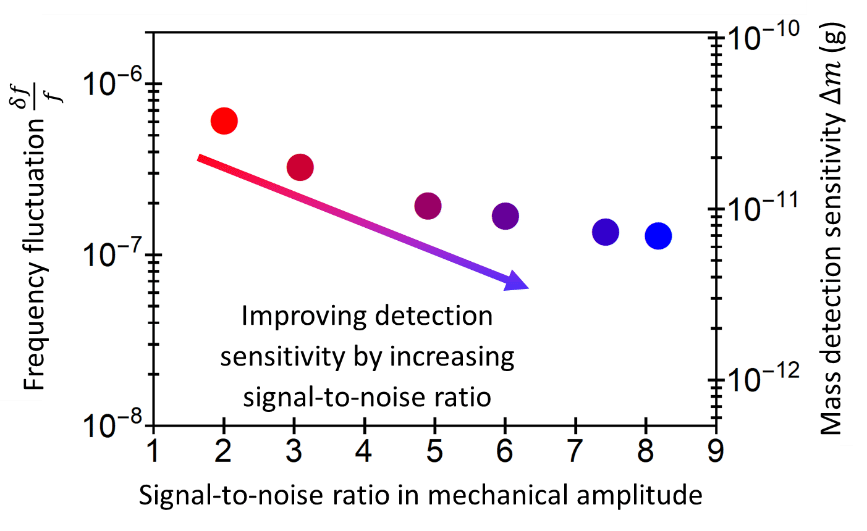

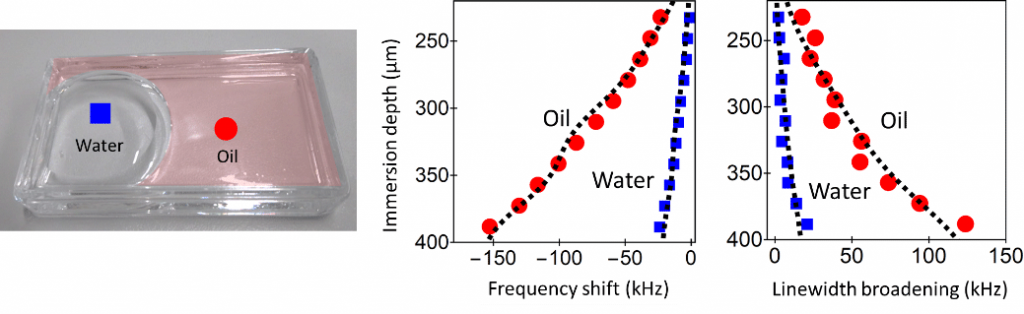

The fabricated sensing device consists of a fine glass element in the form of two connected bottles. By attaching one of the bottles to an optical fibre and inserting the other into the liquid, we succeeded in detecting the mechanical vibration of the in-liquid bottle with high sensitivity using light (Fig. 1). In addition, by evaluating the amount of vibration frequency fluctuation, we found that the limit of mass detection was a few picograms (10 -12 g) (Fig. 2). This value is about three orders of magnitude better than that of conventional quartz resonator sensors and corresponds to a sensitivity that can detect a single bacterium. We also confirmed through experiments in which water and oil were phase-separated that the properties of the liquid at the desired location could be evaluated (Fig. 3).

Key points of technology

- To achieve highly sensitive measurements using light, it is essential to avoid degradation of optical properties due to light leakage into liquids. We therefore adjusted the size of the connection between the two bottles of the sensing device so that light is trapped in one (the in-air bottle) and does not leak into the liquid. Since the mechanical vibrations of the two bottles interact with each other, we can detect the vibrations of the bottle in the liquid by reading the mechanical vibrations of the bottle in air with light. This enables highly sensitive measurements that avoid degradation of optical properties.

- Another point that makes sensitive measurements possible is the strong light confinement in the bottle. The Q-factor, which is given as the ratio of the resonator’s centre frequency to the full-width at half-maximum, is the index of the degree of optical confinements. The optical Q-factor of our sensor is 1.65 x 107, which is higher than that of conventional optical resonators. The Q-factor for mechanical resonance also influences the detection sensitivity, that is, the higher the Q-value, the easier it is to catch small vibrations. The mechanical Q-factor of our device is 2.8 × 103 in air, which is higher than that of typical mechanical resonators.

Future developments

This sensing technology should enable applications that are difficult to achieve with conventional sensors, such as high-resolution detection of particles at desired locations in liquids, concentration distribution mapping of heterogeneous solutions, and local viscosity evaluation in complex liquids such as gels. The ability to coat the glass surface with metal and a self-assembled film would also enable us to utilise it as a biosensor to detect specific viruses and biomolecules in liquids. The ability to detect the signal with an optical fibre in the communication wavelength band would also expand its usage to function as an IoT sensor.

Comment on this article below or via Twitter: @IoTNow_OR @jcIoTnow